Callidus Wells & Pipelines Solution Center

Latest focus:

Disruptive Well Abandonment & Decommissioning Technology

Callidus, smart and sharp.

Callidus Wells & Pipeline Solution Center is an innovative Technology Center which is able to discover, proof, build certify and deploy new technology and solutions for the Oil & Gas industry. By using an analytic and methodic research, development, engineering and production process Callidus reduces the time to market considerable with traditional companies in our field.

Groundbreaking solutions to cut costs.

In the recent year Callidus developed several disruptive technologies for well construction and well completion in close cooperation with major oil and gas producers.

Callidus supplied several special well intervention solutions and tools when well completion or production problems occurred unplanned at our customers. Below you find examples of the solutions we supplied, up to know all with a 100% success rate.

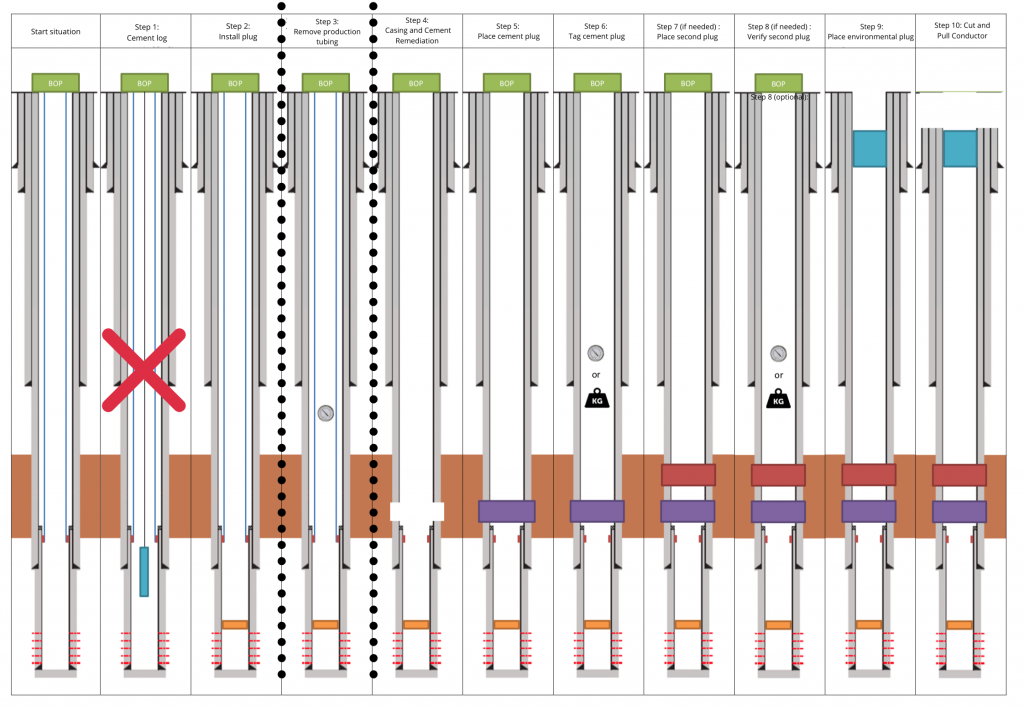

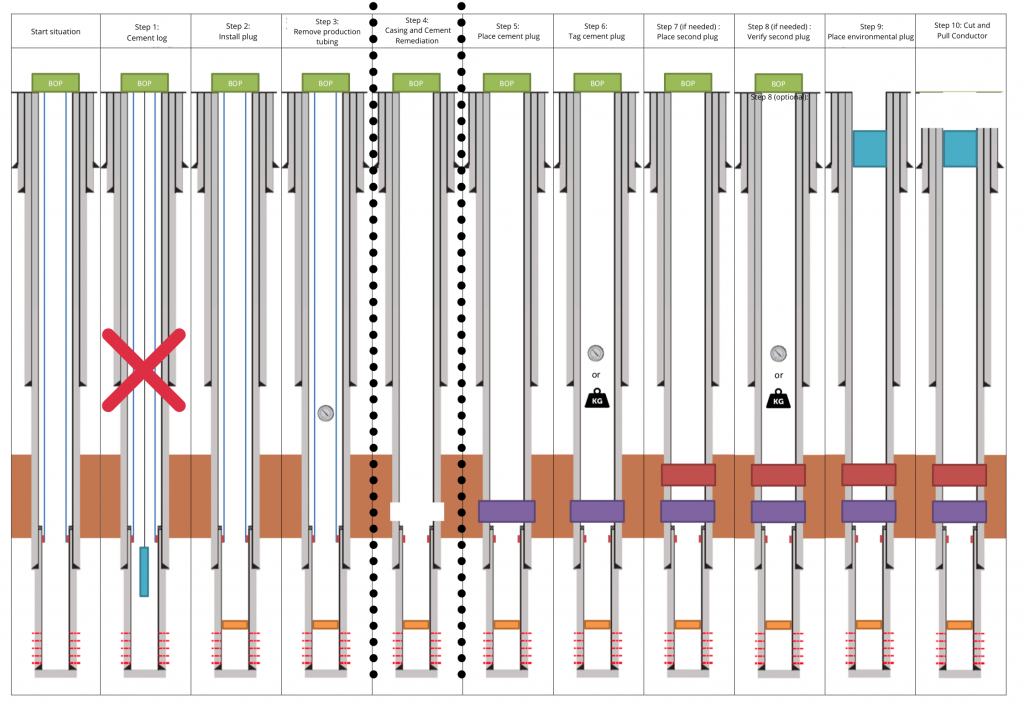

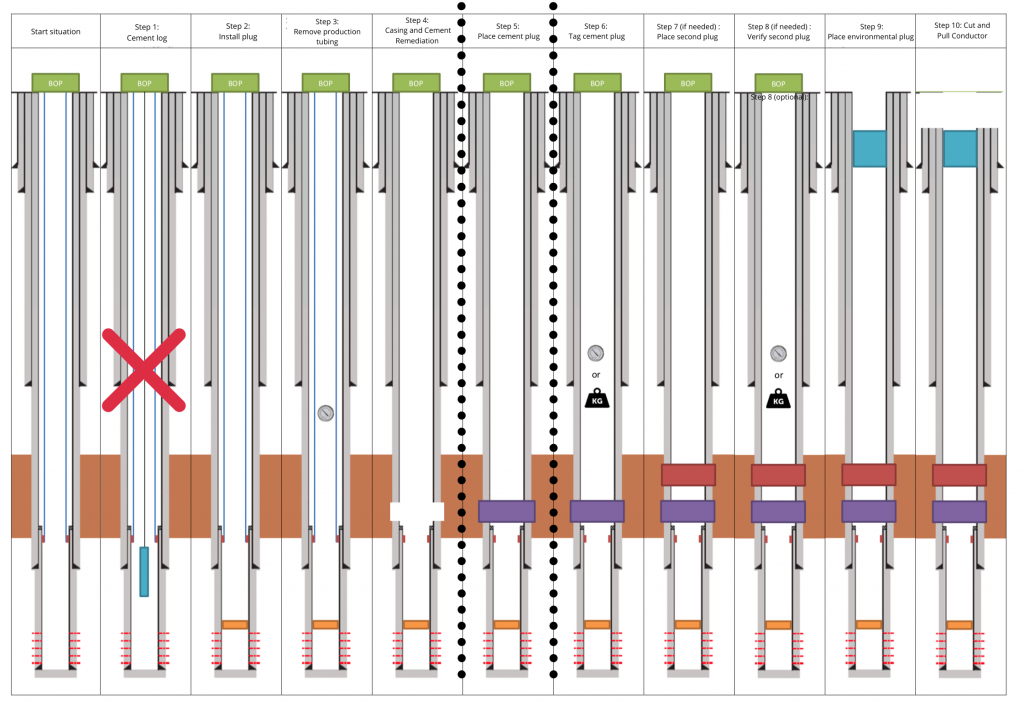

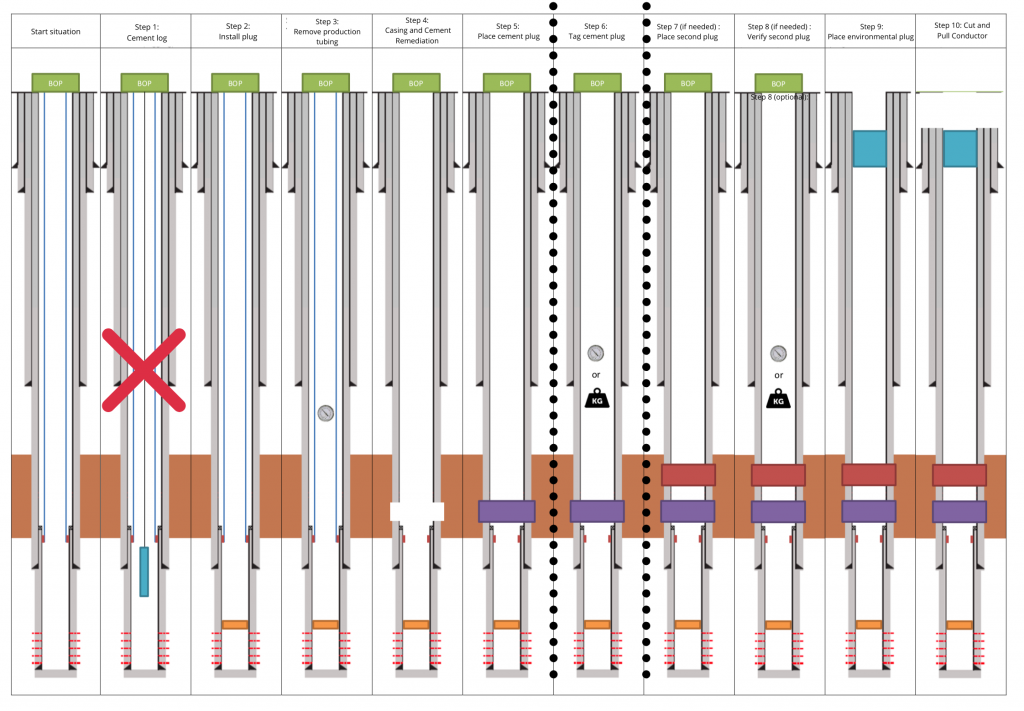

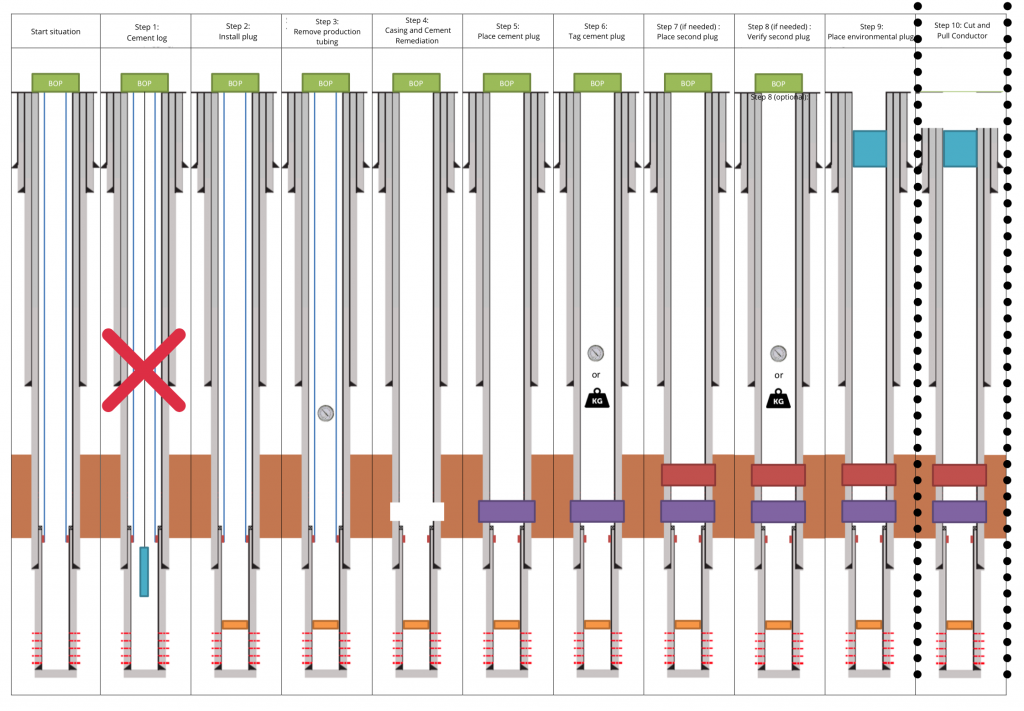

Latest Callidus focus is the development and supply to the market of disruptive Rigless well abandoment and decomisioning technology, related equipment and services. The current development portfolio covers full regulatory steps according market guiding authority regulations like Norsok and NoGepa 45. Callidus covered all operational steps in a Rigless way including high speed casing milling. Further development and deployment takes place jointly with major oil and gas producers and innovative service partners.

Latest disruptive well abandonment and decommissioning technology

Rigless Casing Window Milling

Callidus has developed and patented a disruptive method of casing window milling and cement remediation on coil, ROP rates expected: 15 m / hour, more information following soon.

Vibrating Cement Injectors

Callidus has developed and patented a disruptive method for optimized injection of cement plugs combined with sealant which unfolds the opportunity to create a high quality cement barrier with optimized formation bonding and which is 100% gastight. More information following soon.

Wireline Cement Plug Verification

Callidus has developed and patented a disruptive Rigless method for cement tagging at > 10mT tagging load, by the use of slickline. In 1 single run tagging is performed with proof brought back to surface that the plug has been loaded with the requested load (>10mT). More information following soon.

Rigless Well Head Removal

Callidus has developed and patented a disruptive rigless method for wellhead removal, the required force to move the wellhead after cutting is supplied by an hydraulic actuator which breaks the remaining bridges after abrasive jetting and the friction around the pipe. This reduces the pulling force with >80% which unfolds the way to avoid using a rig. For Offshore Exploration wellheads this opens the way to use smaller ships with lower crane capacity to cut costs. The technology is also suitable for pulling platform legs from 3-6 m below seabed. More information following soon.

Trenchless Pipeline Removal

Callidus developed and patented a method to easily remove abandoned pipelines in a trenchless way with a span of more than 300m. This technology was originally designed for oil or gas pipelines of steel, but could also be applied to alternative materials which are plastic deformable like for example HDPE. Available for pipe sizes: 2,5″- 30″.

Previous developed disruptive technology

SOCCS Drilling Technology

Shell Open Hole Continues Casing System is a disruptive technology developed to strongly reduce the cost for drilling wells. This technology opens the way to automated patch drilling. The well has a full mono diameter bore hole.

The casing is manufactured on site from coils of strip material, the borehole stability is guaranteed instantly and directly behind the bit which covers the challenges of drilling in unstable formations . Because of this continues borehole stability, the technology is also applicable for drilling horizontal pipelines over extreme lengths larger than 2500 m. The demonstrated pipe size 4,5″.

Project lead time: from first idea of folding a pipe inside out to full setup and first 500m drilling demonstration 2,5 years.

Expandable Mono Diameter

Expandable Mono Diameter diameter technology is a disruptive technology to reach deeper production zones or cross unstable formations without losing well bore cross sectional area or ID.

This technology including downhole toolstring is supplied to the market in 6-5/8” , 9-5/8” and 11-3/4”.

CRA Thin Clad Tubing Corrossion Protection

Thin Clad CRA is a disruptive technology for cladding an endless high grade metal alloy corrosion protective layer in the casing or tubing of a well after it is installed. This technology strongly reduces costs because the casing could be of low grade steel, composites or plastics.

The layer can vary in wall thickness, but is just a few mm thick depending on the application the right thickness can be selected. Originally the technology is developed for sour gas wells but is also applicable for wells with a variety of corrosion challenges, like geothermal wells. Applications for pipelines are also possible. An application in HDPE pipelines for drinking water in area’s with soil contamination is also envisioned.

The demonstrated pipe size is 5″.

Stepchange Wireline unit

Together with NAM and partners Callidus developed a concept for optimized slickline operations from safety and automation perspective.

Contact us

Do you want to find out more about Callidus or do you want to contact us about our solutions? Down below you can find our contact information. We’re happy to help you.

Operations Headquarter-Europe / workshop:

Apollo 9

8448CL Heerenveen

The Netherlands

Europe

Innovations HQ:

Rottumerweg 19

8445 PA Heerenveen

The Netherlands

Europe

Global Service Support Centers

The Netherlands – North Sea – Groningen field area

Oosteinde 1

9431AT Westerbork

+31 85 5273 4600

United Kingdom – North Sea – Aberdeen area

WellGear House

Drumoak Business Park

Drumoak

AB31 5AZ

+44 1224 900730

USA – Gulf of Mexico area

1116 Petroleum Pkwy

Broussard LA 70518

+1 337 364 9877

West-Africa area

Candy Vista Mar Building, First Floor

Paseo Marítimo

PO BOX 834

Bata – LITORAL

+44 20 3958 3133

More to follow soon!

© 2025 Callidus Wells & Pipelines Solution Center B.V. All rights reserved. Powered by: Clicksa.nl